线簧插孔的质量检查Quality Inspection of the Wire Spring Jack

2024-07-26 来自: 华海电器 浏览次数:

1. 接触性能:

良好的线簧插孔应具有低而稳定的接触电阻。可以通过专业的电阻测试设备来检测,接触电阻越小,电流传输越稳定,信号损失越小。

接触稳定性高,在多次插拔后仍能保持良好的接触。例如,经过数千次插拔后,测量其接触电阻是否有明显变化。

2. 插拔力:

插拔力适中,既不能过松导致接触不良,也不能过紧增加插拔难度和磨损。可以用插拔力测试仪器进行测量。

举例来说,如果插拔力过小,插孔与插头容易松动脱落;若插拔力过大,频繁插拔可能会损坏插孔或插头。

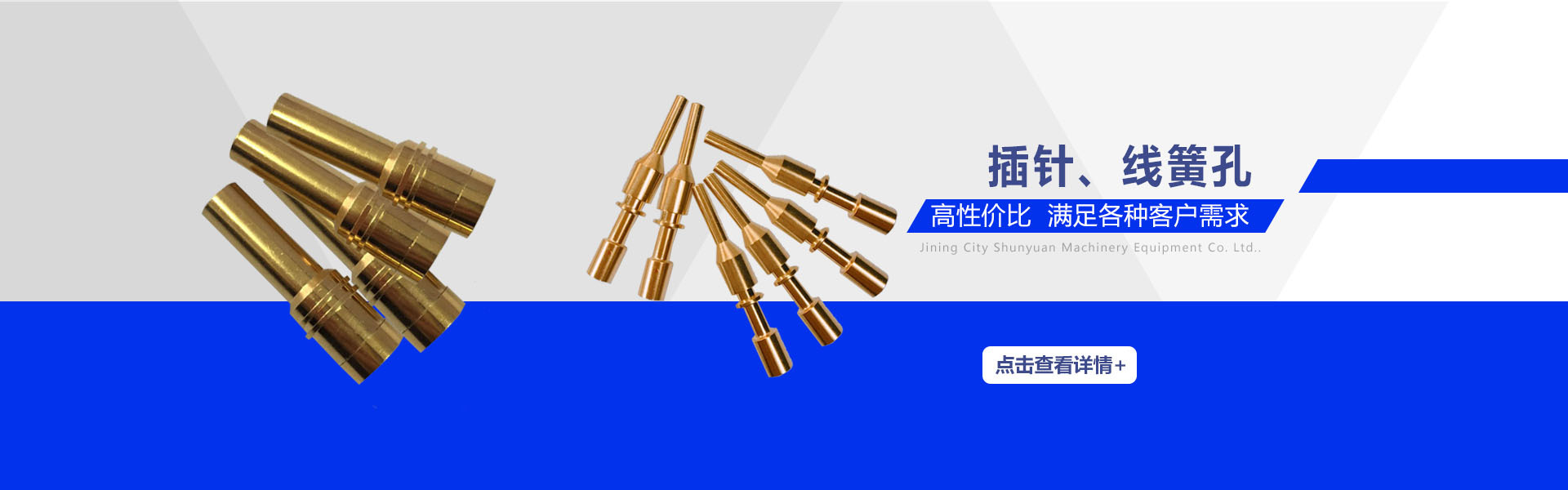

3. 材料质量:

插孔的金属部件通常采用导电性良好且耐磨的材料,如铜合金。优质的材料能保证良好的导电性和耐久性。

绝缘部分应具有良好的绝缘性能和耐高温特性。比如,在高温环境下不会变形或失去绝缘能力。

4. 结构设计:

合理的结构设计能保证插孔与插头的紧密配合,减少接触不良的可能性。

例如,一些插孔采用了特殊的防松动结构,能有效防止插头在使用过程中松动。

5. 制造工艺:

精良的制造工艺体现在插孔的尺寸精度、表面粗糙度等方面。尺寸精度高可保证良好的接触,表面粗糙度低能减少磨损。

观察插孔的外观,无明显的瑕疵、毛刺、划痕等。

6. 环境适应性:

能够在不同的环境条件下正常工作,如温度、湿度、振动等。

可以通过模拟不同的环境条件进行测试,判断其在恶劣环境下的性能稳定性。

7. 品牌和厂家信誉:

知名品牌和有良好口碑的厂家通常在质量控制方面更为严格。

参考其他用户的评价和使用经验也是判断质量的一个重要依据。

总之,要综合考虑以上多个因素,才能较为准确地判断线簧插孔的质量好坏。

Quality Inspection of the Wire Spring Jack

1. Contact performance:

Good wire spring jack should have a low and stable contact resistance. It can be detected by professional resistance testing equipment. The smaller the contact resistance, the more stable the current transmission, and the smaller the signal loss.

High contact stability and good contact after multiple plugs. For example, after thousands of plugs and plugs, measure whether the contact resistance changes significantly.

2. Insertion and Withdrawal Force:

The insertion and pulling force is moderate, neither too loose to lead to poor contact, nor too tight to increase the difficulty of insertion and wear. It can be measured with a plugging force test instrument.

For example, if the plug and pull force is too small, the jack and plug are easy to loosen and fall off; if the plug and pull force is too large, frequent plug and pull may damage the jack or plug.

3. Material quality:

Metal parts of the jack are usually well-conductive and wear-resistant materials, such as copper alloys. High-quality materials can ensure good electrical conductivity and durability.

The insulation part shall have good insulation performance and high temperature resistance characteristics. For example, it does not deform or lose insulation at high temperatures.

4. Structural design:

Reasonable structural design can ensure the close fit of the jack and the plug, and reduce the possibility of poor contact.

For example, some jack holes use a special anti-loosening structure, which can effectively prevent the plug from becoming loose during use.

5. Manufacturing process:

Excellent manufacturing process is reflected in the jack size accuracy, surface roughness and so on aspects. High dimensional accuracy can ensure good contact, and low surface roughness can reduce wear.

Observe the appearance of the jack, no obvious defects, burrs, scratches, etc.

6. Environmental adaptability:

Ability to work normally under different environmental conditions, such as temperature, humidity, vibration, etc.

It can be tested to simulate different environmental conditions.

7.Brand and manufacturer reputation:

Well-known brands and manufacturers with a good reputation are usually more strict in quality control.

Referring to the evaluation and use experience of other users is also an important basis for judging the quality.

In summary, evaluating the quality of spring contacts involves considering multiple factors to accurately determine their performance and reliability